Solder and crimp splices: Variants and application

Solder and crimp splices provide the electrical connection of cables and wires; solder splices may also be used to terminate shielding. Soldering is a conventional method for reliable electrical connection of solderable metals. This solder moistens the metals without, however, fusing them. A distinction can be made between brazing and soft soldering. In brazing, temperatures of more than 450° C are attained, with solders made primarily of silver and brass being used. Since the brazing process results in strong and airtight joints, this is particularly used on copper pipes in gas and water installation applications. In contrast, soft soldering takes place in the temperature range <300 °C and is, therefore, easier to realize. The solders predominantly used are tin, lead, and various alloys. Typical applications for solder and crimp splices applications include all areas of electrical engineering, and occasionally also low-temperature piping. As an attractive alternative to conventional soldering, GREMCO offers two different product groups for the reliable connection of electrical wires and cables. These are our

- FTLV® solder splices and our

- FITCO®Seal crimp splices.

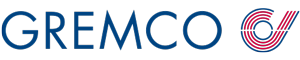

FTLV® solder splices

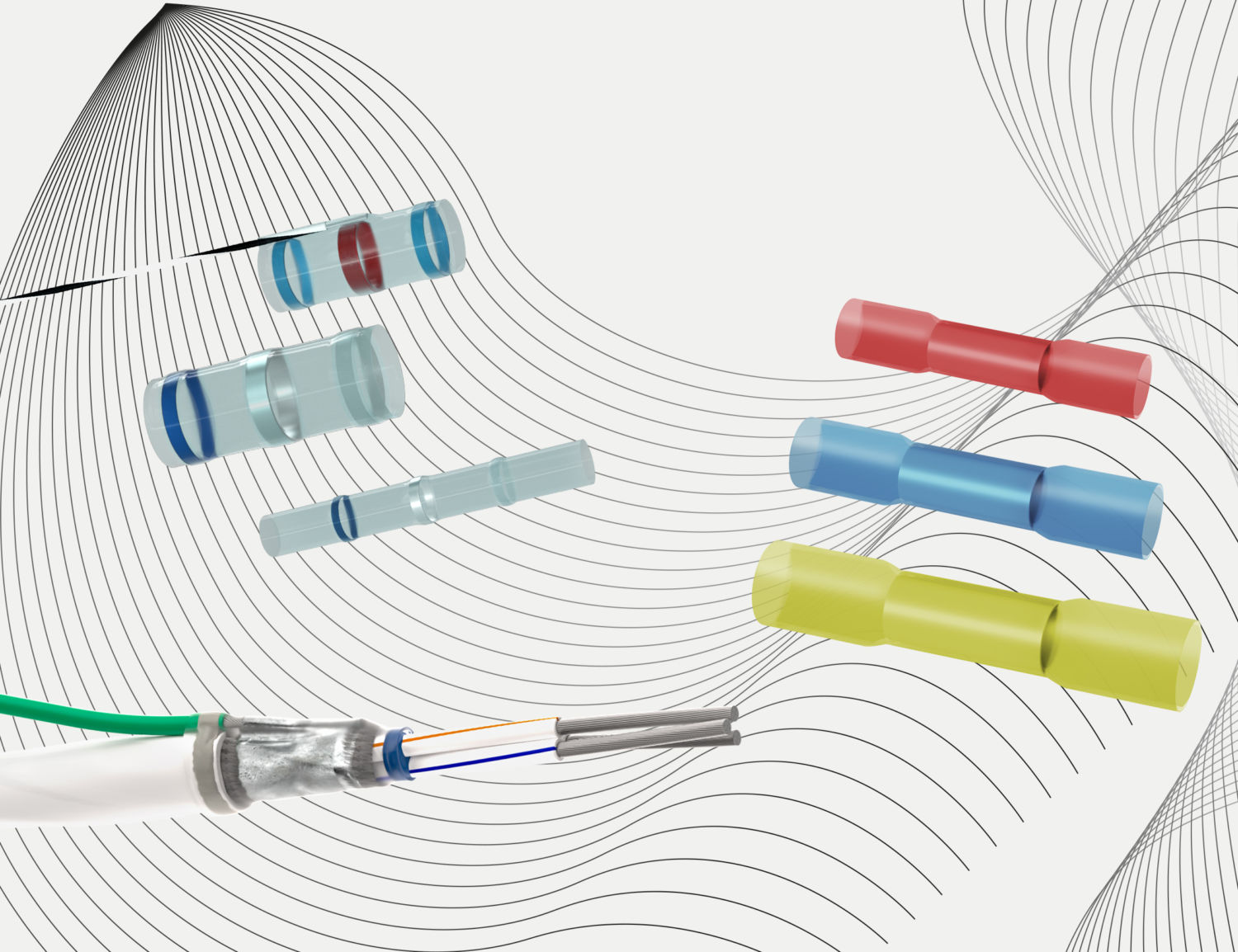

FTLV® heat-shrinkable solder sleeves consist of transparent heat-shrinkable tubing containing a metal solder ring and two sealing rings made of heat-melting plastic. Upon heating with special heat sources (hot air or infrared), the solder ring melts and the shrink tubing contracts, forming a very tight, protected connection of the electrical leads inside. These components ensure a reliable, fully insulated electrical connection of two or more wires. Furthermore, they are used for electrical shield terminations. In addition to the demonstrably reproducible electrical connection quality, these GREMCO products are also characterized by excellent thermal, mechanical and chemical resistance. Likewise, the transparent insulation of the solder connectors allows for easy visual inspection. Our wide product range, which includes numerous different material combinations, provides solutions for diverse requirement profiles and temperature ranges. Accordingly, they are ideally suited for various applications in almost all industrial sectors such as aerospace engineering, the automotive industry, environmental technology, or medical equipment.

All FTLV® solder splices may be reliably processed with relatively simple means. An example of a common FTVL® solder sleeve is our FTLV®-NT. Featuring an installed temperature resistance of -55 °C to 105 °C, this connector is based on a combination of polyolefin heat shrink tubing and eutectic solder. Alternatives more resistant to temperature consist of temperature-resistant heat shrink tubing (-55 °C to 150 °C) as well as alternative solder materials. Both variants are mainly used in shield termination technology as well as for electrical connection and contacting connector pins. One particularity presents our FTLV SWT 9551, classified as ROHS-compliant.

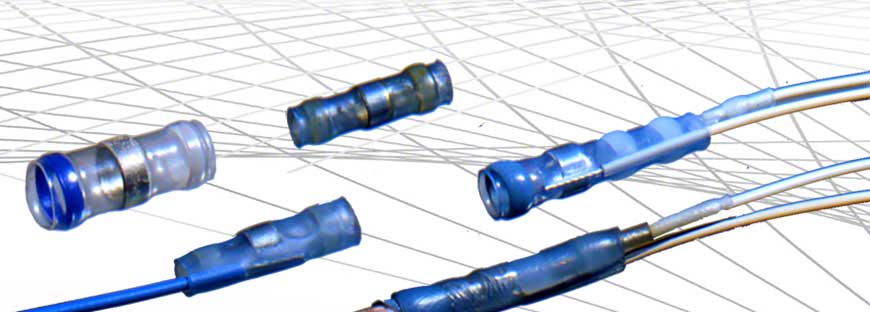

FITCO®Seal crimp splices

Yet another variant for connecting electrical wires and cables is represented by our FITCO®Seal crimp connectors. These consist of a crimp sleeve made of tinned copper in combination with an adhesive-coated heat-shrinkable tubing sleeve. Unlike the processing of solder sleeves, two separate operations are necessary here. First, the stripped electrical wires are fixed in the crimp sleeve using a special crimping tool. Subsequently, the shrink sleeve is heated until the adhesive emerges evenly on both sides. This ensures high mechanical strength and water tightness of the connection. A primary application of FITCO®Seal crimp connectors lies in the after-market sector of the automotive industry. The conductor cross-section range covers between 0.5 mm² and 6 mm² and is accommodated by three different product sizes (FTS-1, FTS-2, and FTS-3). The sizes are color-coded (red, blue, and yellow). Guaranteed temperature range of these is from -55 °C to 105 °C. The specified shrink temperature is 120 °C.

We would be pleased to advise you on our product range and the possible applications of the Fitcoflex woven hose polyethylene. Please contact us!