ePTFE membranes in battery vents

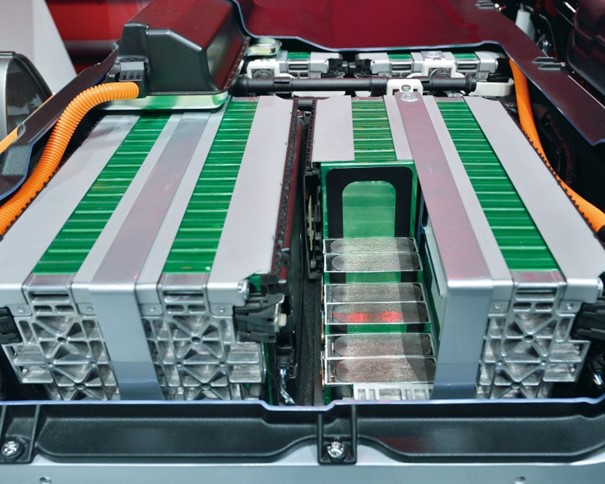

The number of electric and hybrid vehicles is increasing rapidly in Germany. For this reason, the lithium-ion batteries required for these vehicles are also becoming ever more important. These rechargeable energy stores feature a high energy quotient per unit volume and are assembled in battery blocks for utilization as a drive source in automobiles. Particularly for application in motorized vehicles, these lithium-ion batteries naturally require adequate protection against their demanding environmental conditions, as well as a ventilation system to compensate for temperature or pressure fluctuations. A dual-stage ventilation solution with ePTFE membranes has established itself as the most functional option to achieve this. Level 1 ensures pressure compensation, while at the same time preventing the ingress of foreign bodies and water. During level 2, the aeration element is opened. Accumulating gases thus escape, a rise in temperature and pressure is prevented, and additive damage to the battery cells is avoided.

Ventilation to protect the battery enclosure

Typically, a battery housing provides a sealed enclosure made of metal or plastic to protect the contained batteries from external influences such as weather, dust, or abrasion, thus preventing damage to the battery cells. However, as a sealed element, the absence of interchangeability leaves a battery enclosure highly susceptible to damage due to both excessive temperatures within the enclosure and excessive pressure gradients between the interior of the enclosure and the surrounding environment. Both these problems can occur at any time during vehicle operation as a result of heat generation in the battery cells, fluctuating ambient temperature, altitude changes, or varying ambient pressure, and can lead to damage to the battery cells and seals. Continuous stress may result in leaks and explosions. A two-stage ventilation solution is necessary to counteract this, allowing gases generated by rapid pressure increases to escape and preventing excessive temperature rises in the enclosure.

A detailed look at the inside of a lithium-ion battery is useful to understand the necessity for this pressure equalization. In general, a battery pack is composed of two connected elements, whose connection point is provided with a seal. Precisely this seal suffers stress as the pressure gradient increases. However, since most manufacturers of electronically powered vehicles offer a warranty of up to eight years, the battery cells are expected to have a corresponding operating life. Adequate pressure equalization considerably reduces pressure differences and thus contributes significantly to the protection and longevity of the seal and enclosure.

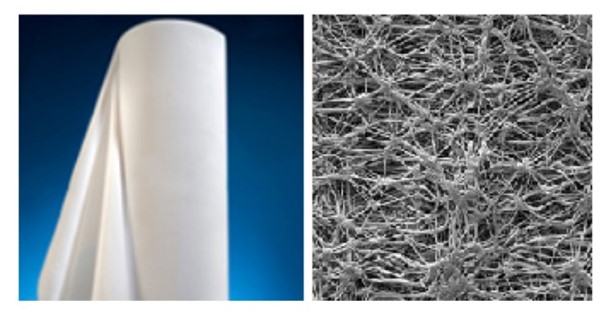

Level 1 ventilation by means of ePTFE membranes

Level 1 ventilation, also referred to as passive ventilation, is usually a ventilation system comprising expanded polytetrafluoroethylene (ePTFE) which, simultaneously, provides pressure equalization while preventing contamination of the enclosure during the ventilation process. The ePTFE membranes contained (see Figure 2) appear to be opaque to the human eye and ensure protection against the ingress of even the smallest particles. Contrary to appearances, however, an ePTFE membrane contains numerous openings measuring less than one micrometer in maximum diameter, allowing it to remain passable to gases and enabling pressure equalization. Depending on the expected contaminants, the venting elements can be specifically adapted. For example, specialization of a common battery housing is possible to withstand water with a pressure of up to 690 millibars.

ePTFE membranes

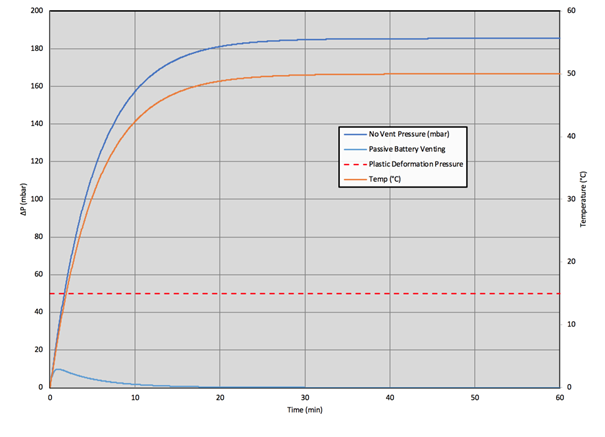

Owing to their mechanical resistance, chemical inertness, as well as high-temperature resistance, GREMCO’s FITCO® ePTFE membranes, provide safe, effective, and long-term protection against various impurities such as water, oil, dust, or other particles and liquids. The effectiveness of pressure reduction in the first ventilation stage using FITCO® ePTFE membranes is conveyed utilizing Figure 3. For instance, a battery case without a ventilation system is exposed to a temperature increase of 50 °C within one hour. This is approximately equivalent to an automobile scenario that is started at cold outside temperatures and subsequently driven at high speed. Pressure gradients of up to 180 millibars result. A ventilation system with an ePTFE membrane can reduce this value to a maximum of 10 millibars.

Ventilation level 2

Contrary to level 1, which remedies continuously developing pressure gradients in the battery housing, such a procedure may not be possible in the scenario of a “thermal runaway”. Level 2 vents (active vents) are designed to solve this problem. The vent element is opened completely, so that strongly expanding gases are released in a controlled manner, preventing further damage to the remaining cells and uncontrolled explosions in the enclosure. Usually, this works using mechanical functions initiating ventilation in a given scenario. This prevents the development of critical pressure gradients leading to catastrophic failure as a result of “thermal runaway”, i.e. rapid occurrence of gases and high temperatures.

The interaction of active and passive ventilation can prevent the battery housing from rupturing, as shown in Figure 3. An enclosure that would ordinarily rupture under a pressure of 1,500 millibars has been fitted with an active ventilation element that opens at 500 millibars. This system reduces the pressure gradient to about 750 millibars, which reliably prevents rupture.

We would be pleased to advise you on our product range and the possible applications of the Fitcoflex woven hose polyethylene. Please contact us!