FITCOTUBE® heat shrinkable tubing: Manufacturing

GREMCO’s versatile FITCOTUBE® heat shrinkable tubing is characterized by high mechanical and chemical resistance with consistently outstanding surface quality as well as tight diameter tolerances and is excellently suited for the protection of wires, cables and hoses against mechanical, thermal, and chemical influences. The tubing is available in different qualities and, if required, with various national and international approvals as well as specifications and is therefore excellently suited for a wide range of applications in the automotive, environmental, medical, and aerospace industries. FITCOTUBE® heat shrinkable tubing owes its application-optimized properties to a sophisticated production process, which can be divided into three basic production steps which are explained below.

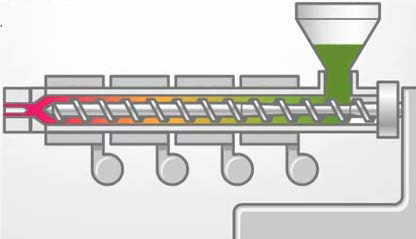

Extrusion process

In preparation for the FITCOTUBE® heat shrinkable tubing extrusion process, the desired material is first compounded. For this purpose, the common base polymer, for example, polyolefin, is improved with various additives such as UV stabilizers, flame-retardant halogens, masterbatches and crosslinking accelerators that enable efficient crosslinking. This ensures that the material is adapted to the requirements of the desired application. The granules are subsequently fed to the extruder via a hopper. In the barrel, the material is first melted by the application of heat and finally pressed into tubular form. This process is known as melt extrusion and is a continuous manufacturing process.

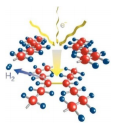

Irradiation/crosslinking

In the second production step, the extruded plastic tubing is specifically irradiated with electrons, resulting in what is known as crosslinking. In this way, hydrogen atoms are knocked out of the existing molecular bond. The carbon atoms that have now become free form cross-links in the molecular structure. The result is a three-dimensional network structure characterized by these cross-links. As a result, FITCOTUBE® heat shrinkable tubing acquires its characteristic elastic shape memory.

Expanding the tubing

In the third and final manufacturing step, the expansion process, FITCOTUBE® heat shrinkable tubing is continuously heated still below the melting point and expanded with compressed air followed by a cooling procedure. In this way, the diameter of the tubing is increased by a factor of 2-4. This allows easy installation of FITCOTUBE® products over components with significantly larger diameters without damage. Depending on customer requirements, the finished tubing can either be coiled or cut to the desired dimensions. This is followed by final inspection and clean, economic packaging.

We would be pleased to advise you on our product range and the possible applications of the Fitcoflex woven hose polyethylene. Please contact us!