The process of radiation crosslinking for heat shrinkable tubing

Our extensive FITCOTUBE® heat shrinkable tubing represents a key product group in GREMCO’s diverse portfolio. Generally, they are characterized by a high level of resistance to a wide range of external influences while maintaining consistently high surface quality. Thus, the heat shrinkable tubing provides reliable protection for hoses, wires and cables against mechanical, chemical and thermal influences. Moreover, FITCOTUBE® heat shrinkable tubing is featuring excellent UV resistance, outstanding electrical properties, and permanent operating temperatures of up to 260°C (short-term up to 400°C). Depending on the respective requirements, FITCOTUBE® heat shrinkable tubing is available in various versions and qualities along with specified national and international approvals. Consequently, the tubing is designed to meet the special requirements of the automotive, environmental, medical and aerospace industries. The consistently high quality of FITCOTUBE® heat shrinkable tubing is guaranteed by a sophisticated manufacturing process. The central aspect of which is the process of radiation crosslinking.

Radiation crosslinking

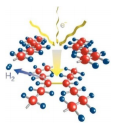

The basic plastic material is loaded with additives, formed into granules and then fed into an extruder. This improves the materials properties. After extrusion, the extruded tubes are radiation crosslinked by a high-energy electron beam. This so-called irradiation results in the detachment and removal of hydrogen atoms from their molecular structure. This enables the associated carbon atoms to establish reciprocal cross-links, creating a three-dimensional network structure. Precisely this three-dimensional network structure is responsible for the characteristic elastic shape memory of FITCOTUBE® heat shrinkable tubing as well as its mechanical, chemical and thermal properties. Due to the elastic memory, the heat shrinkable tubing will restore its original shape independently after an intermediate mechanical deformation (expansion). Especially concerning simple applications on complicated components, such as cabling systems or hose and tube connections with different diameters, which are often found in the automotive and aerospace industries, this is significant.

Chemical crosslinking

As the only reliable alternative to the radiation crosslinking process for the professional production of shrink products, the chemical crosslinking process should be mentioned. This process is sometimes used, for example, in the production of shrink caps and heat-shrinkable molded parts (junctions and connector end housings). Rather than irradiation, special chemical additives are added to the granules, which triggers the crosslinking process. In contrast to the radiation crosslinking process, an extruder is not used to form the products. Instead, they are molded by injection molding. Due to the higher production speed, the very high process reliability and the lack of risk of chemical residues, the radiation crosslinking process can be classified as the superior process in continuous production contexts such as extrusion.

We would be pleased to advise you on our product range and the possible applications of the Fitcoflex woven hose polyethylene. Please contact us!