“Even in medical technology, we stand out with our many years of experience and our sound expert knowledge.”

JÜRGEN WEBER, Sales Engineer

Ask us about solutions for your special application.

Contact

“Even in medical technology, we stand out with our many years of experience and our sound expert knowledge.”

JÜRGEN WEBER, Sales Engineer

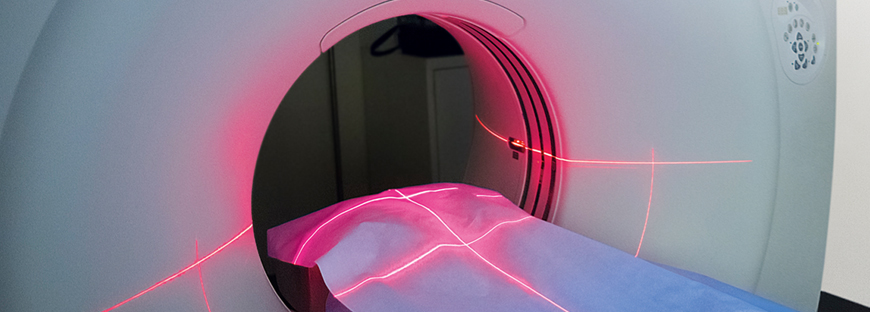

At GREMCO, we design, develop, produce and supply customized and special cables, cable harnesses, hoses and catheters for medical technology.

GREMCO already has many years of experience as a manufacturer of a wide variety of protective hoses used in medical technology. We are able to supply both, complete system solutions and custom-made products. Our heat-shrink tubing, multi-lumen tubing and extrudates are successfully used in medical technology owing to their excellent chemical, thermal and physical properties. During production, we adhere to one clear demand: the highest development standards, the most state-of-the-art, economical manufacturing methods and GREMCO’s exemplary reliability. Ask us today!

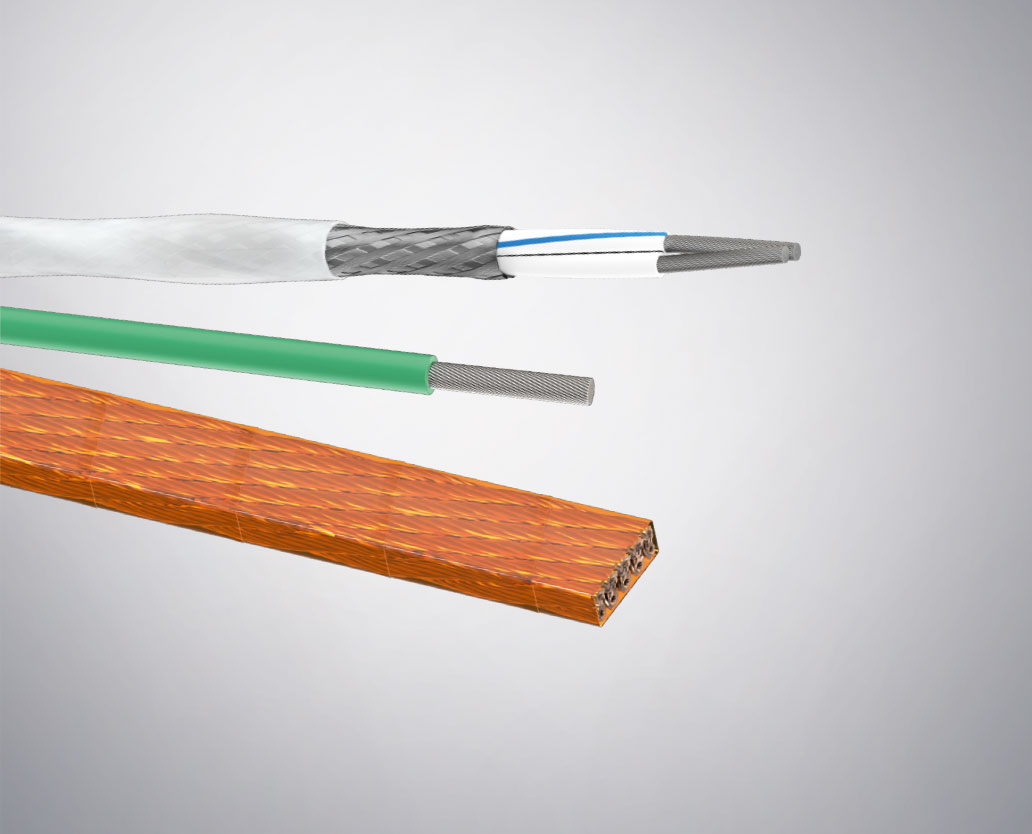

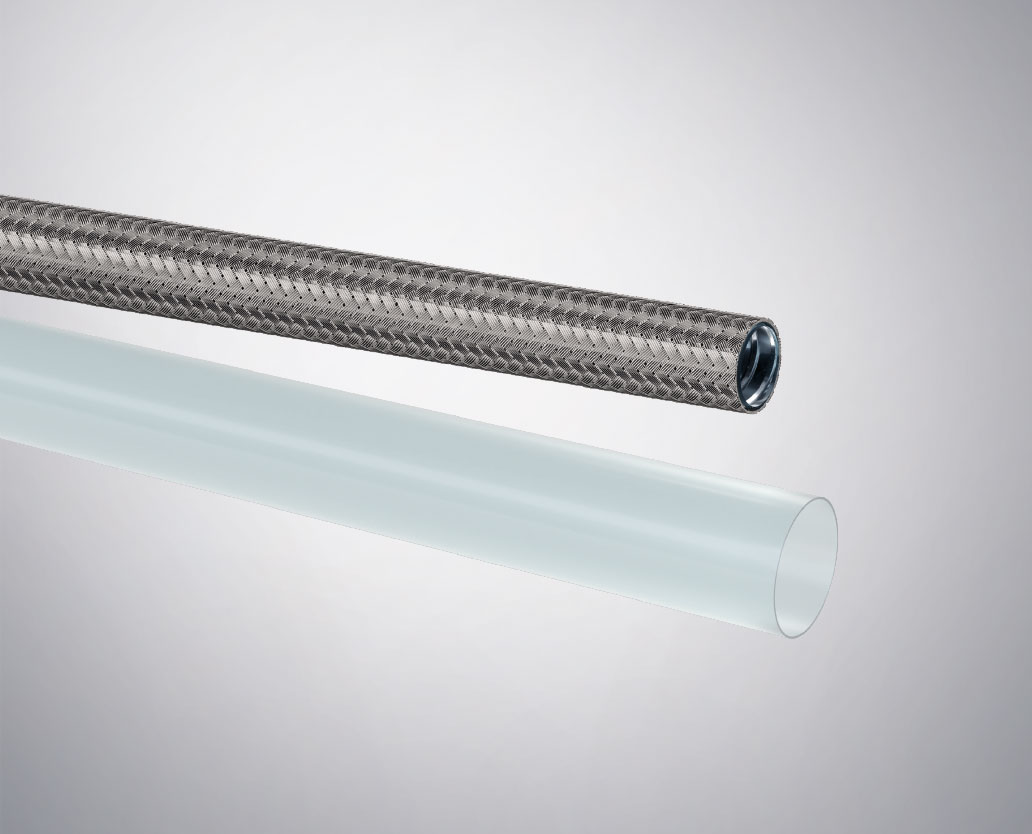

Alongside wire harnessing, we are also experts in media-carrying systems. Our range of products comprises single- and multi-lumen catheter tubes made from all conventional materials as well as thin, flexible and yet especially resistant silicon and fabric-reinforced tubing. These, and multi-chamber tubing, are just a few of the outstanding products, which we produce in close collaboration with our international cooperation partners.

With more than three decades of experience in the field of medical technology, we have successively built up a specialized product portfolio for medical technology and have in-depth expertise in production as well as applications and customer requirements in this market segment. Some of our products for medical technology are manufactured in clean room production and meet the high requirements of medical technology. Our product portfolio includes:

Our range of general medical tubing includes single and multi-lumen products made from a variety of materials: PTFE, PFA, polyurethane, to name but a few. They are used either as consumables for production or as components of medical devices.

| Material: Polyolefin | Temperature range: – 55°C to + 105°C | Request now Datasheet |

| Color: Transparent, others on request | Shrinking temperature: +60°C | |

| Key feature: complies with USP class VI; compatible with gamma and ETO sterilization | Shrinking ratio: 2:1 |

| Material: Polyolefin | Temperature range: – 55°C to + 105°C | Request now Datasheet |

| Color: transparent | Shrinking temperature: > +110°C | |

| Key features: free of heavy metals; compatible with gamma and ETO sterilization | Shrinking ratio: 2.5:1 |

| Material: Polyolefin | Temperature range: – 40°C to + 105°C | Request now Datasheet |

| Color: transparent | Shrinking temperature: +130°C to +250°C | |

| Key features: compliant with ISO 10993-1 | Shrinking ratio: 2:1/3:1 |

| Material: Radiation cross-linked silicone | Temperature range: – 50°C to + 200°C | Request now Datasheet |

| Color: grey | Shrinking temperature: +140°C | |

| Key features: High temperature resistant, halogen-free | Shrinking ratio: 2:1 |

| Material: Modified FEP | Temperature range: to + 200°C | Request now Datasheet |

| Color: transparent | Shrinking temperature: +215°C | |

| Key features: Chemically resistant, sterilizable, shrinkage begins at low temperatures | Shrinking ratio: 1.6:1 |

| Material: Modified FEP | Temperature range: up to + 205°C (temporarily up to 250°C) | Request now Datasheet |

| Color: transparent | Shrinking temperature: approx. +200°C | |

| Key features: Excellent chemical resistance, high temperature application range | Shrinking ratio: 1.4:1 |

| Material: Polyamide | Temperature range: – 40°C to + 160°C | Request now Datasheet |

| Color: black / grey | Melting point: approx. +245°C | |

| Key features: Halogen-free, self-extinguishing, non-toxic | Approvals: – |

| Material: Polyester | Temperature range: – 70°C to + 150°C | Request now Datasheet |

| Color: black / orange | Melting point: – | |

| Key features: self-wrapping, abraison resistant, easy to apply and remove | Approvals: – |

| Material: PTFE | Temperature range: – 200°C to + 260°C | Request now Datasheet |

| Color: transparent | Key feature: suitable for high temperature environment | |

| Material: Polyether polyurethan | Temperature range: – 25°C to + 85°C | Request now Datasheet |

| Color: grey | Key feature: Microbe and hydrolysis resistant | |

Applications

Properties

Applications

Properties

Applications

Properties

Applications

Properties

Applications

Properties

Whether standard applications, special designs or complete system solutions – we are able to respond quickly to your insulating hose enquiries, help with technical questions and develop solution concepts. We look back on many years of experience in the field of insulating hoses, and we excel owing to our expertise and Germany’s customary premium quality. With GREMCO’s insulating hoses, we are constantly setting new standards through continuous innovation in cooperation with our customers in the automotive, aerospace, environmental and medical engineering industries. In recent years, we have also been continuously building up technical expertise in other industrial sectors and tailoring our products to the needs of our customers.

Our highly qualified experts are looking forward to hearing from you.

Would you like more information about our company and our products? Simply fill out the following contact form completely and send it to us. One of our responsible experts will get back to you as soon as possible.

However, you are also welcome to contact us by phone at any time on

+49 (0)821 27 26 3-01. We are available for you!

Thank you for your message!

Your request has reached us. We will contact you as soon as possible! In urgent cases, we are of course also available for you at any time at

+49 (0)821 27 26 3-01!

Sie Besuchen unsere Englische Website.

Möchten Sie lieber auf Deutsch wechseln?

We need your consent before you can continue to visit our website. If you are under 16 and wish to give your consent to volunteer services, you must ask your parent or guardian for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us improve this website and your experience. Personal data may be processed (e.g. IP addresses), e.g. for personalized ads and content or ad and content measurement. For more information about how we use your data, please see our Privacy Policy. You can revoke or adjust your selection at any time under preferences.

If you are under 16 and wish to give your consent to volunteer services, you must ask your parent or guardian for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us improve this website and your experience. Personal data may be processed (e.g. IP addresses), e.g. for personalized ads and content or ad and content measurement. For more information about how we use your data, please see our Privacy Policy. You can revoke or adjust your selection at any time under preferences. Here you can find an overview of all cookies used. You can give your consent to entire categories or view more information and thus select only certain cookies.